BTA BORE

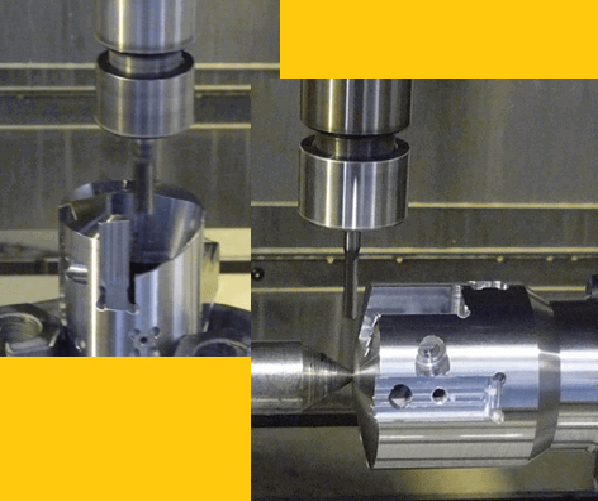

Deep Hole Boring Tools

Improved Concentricity

About

High Quality BTA Deep Hole Drilling Tools. Proudly Made In Britain

Our indexable "SOLID" drill heads are designed to handle diameters ranging from 25 mm to 300 mm, ensuring optimal performance and durability across various applications.

"Push" counter boring indexable drill heads offer a diameter range from 44 mm to 402 mm, providing versatility for a wide range of counter boring tasks.

"Pull" counter boring indexable drill heads support diameters ranging from 40 mm to 254 mm, ensuring efficient material removal and smooth operation.

BTA BORE is a premier provider of tooling solutions for the deep hole boring industry, partnering with a global network of trading partners.

Our BTA (Boring & Trepanning Association) system is meticulously manufactured using high-quality materials and precision engineering, supported by a team of skilled professionals with decades of experience in deep hole drilling.

Our comprehensive range of products and services includes:

- Solid Drilling Heads (STS & DTS) for Push and Pull Boring

- Trepanning heads, Skiving heads, Form boring tools

- Custom Tool Design and Manufacturing for Drill Heads (Counter Boring and Trepanning)

- Metalworking and Industrial Supplies

- BTA Brazed Heads

- Tailored Inserts, Solid Carbide Pads, and Cartridges

- Interchangeable heads compatible with existing boring bars from leading brands, including Sandvik and Botek.

- Exceptional engineering quality coupled with competitive pricing.

- Prompt delivery of BTA drill heads, inserts, and carbide pads.

We Now Offer Sandvik-Style Replacement Deep Hole Drilling Tools & Inserts

Check It Out Today!

CoroDrill 800.24 Style T-MAX drill 424.10 Style

Products

Tailor Made

Special Size! Solid Drill Heads, Trepanning & Counter Boring Heads are available upon request

Trepanning from dia. 88.90 mm to 609.60 mm Counter Boring from dia. 44mm - 402 mm

Articles

Deep Hole Drilling Tools. Proudly Made in Great Britain.

Guide pad breakage is a common problem in BTA (Boring and Trepanning Association) drilling that can lead to tool failure and downtime. Here are some tips to help reduce guide pad breakage in BTA drilling:

Read MoreTool wear: Tool wear is a common problem in BTA deep drilling that can lead to reduced tool life, poor surface finish, and increased costs. Tool wear can be caused by various factors, including excessive heat, high cutting speeds, and incorrect tool geometry.

Read MorePoor surface finish: Poor surface finish can be caused by various factors, including incorrect cutting parameters, poor chip evacuation, tool wear, and vibration. To resolve this issue, you should check the cutting parameters, adjust the feed rate, coolant pressure and flow rate, and ensure proper tool alignment.

Read MoreINTERESTED IN BECOMING ONE OF OUR DISTRIBUTORS?

Get in touch with Export Sales :- export@btabore.com

Our BTA tooling is engineered with a commitment to innovation and precision, effectively addressing the challenges of today’s drilling industry. They provide dependable, consistent performance while reducing downtime. Whether for major industrial initiatives or specialized drilling tasks, our tools offer exceptional reliability, accuracy, and durability.

Contact

Request a quote.

- BTA BORE , 17 King Edwards Road, Ruislip, London

- United Kingdom HA4 7AE

- info@btabore.co.uk

- Mon-Fri - 08:00-17:00