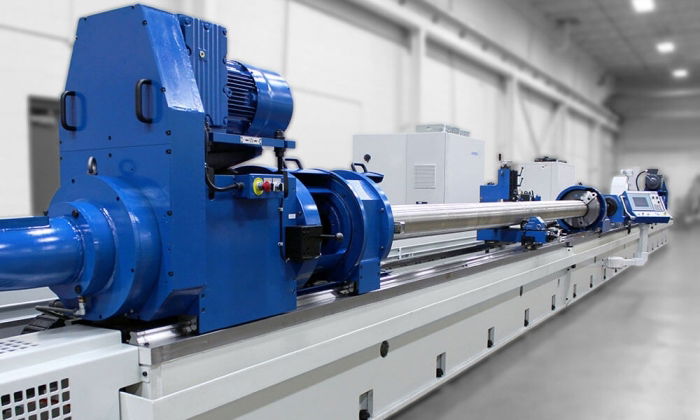

Key Components for BTA Deep Hole Drilling Machines

Key Components for BTA Deep Hole Drilling Machines

Several components are present on typical BTA drilling machines, regardless of configuration.

Drill Guide Bushing

A precision drill guide bushing contacts the workpiece to guide the BTA tool as it prepares to drill . This bushing allows the tool to start in the proper location, and with the correct hole diameter, both essential for accurate deep hole drilling. The drill guide bushing also works to seal against the workpiece to contain the coolant during the drilling process.

Pressure Head

A pressure head seals around the BTA tool and drill guide bushing, introducing the coolant around the outside of the tool, and for chip evacuation throughout the drilling process.

Vibration Dampeners

Vibration dampeners support long drills under the speed of rotation while transmitting torque, stabilizing the tool for an accurate drilling process. These devices are equipped with rotating bearings and inserts that contact the tool to provide the vibration dampening benefits. Longer travel machines may have multiple traveling vibration dampeners, while shorter machines may not require any.

Drilling Spindle

High power, torque precision, and low vibration are important for productive BTA drilling. The spindle transmits the power and torque from the motor, to the tool. Chips and coolant are evacuated through a hole in the center of the spindle during operation.

Coolant System

The reliability and performance of the BTA deep hole drilling process depends heavily on the machine coolant system. A logically designed reservoir system starts by holding coolant, and a high-volume pump groups works to delivery the cutting fluid to the BTA tool. Once the coolant progresses through the metal cutting operation, it is enters the filtration system. Low-micron coolant filtration, and filter condition feedback prevent the accumulation of chips and small particles, leading to less down time, longer tool life, and improved surface finishes.

Coolant Temperature Control

The drilling headstock and coolant pumping system generate heat, which can have a negative impact on drilling factors such as tool life and accuracy, as well as the operating conditions around the machine. To manage the heat, either a heat exchanger or chiller is required to maintain cutting fluid at the proper temperature.